Core Advantage

Highly Customized Service

LTPM has a deep understanding of customer needs and provide customers with highly customized services based on their individual needs for raw materials, processes, output, packaging, etc.

Highly Customized Service

LTPM has a deep understanding of customer needs and provide customers with highly customized services based on their individual needs for raw materials, processes, output, packaging, etc.

FAQ

-

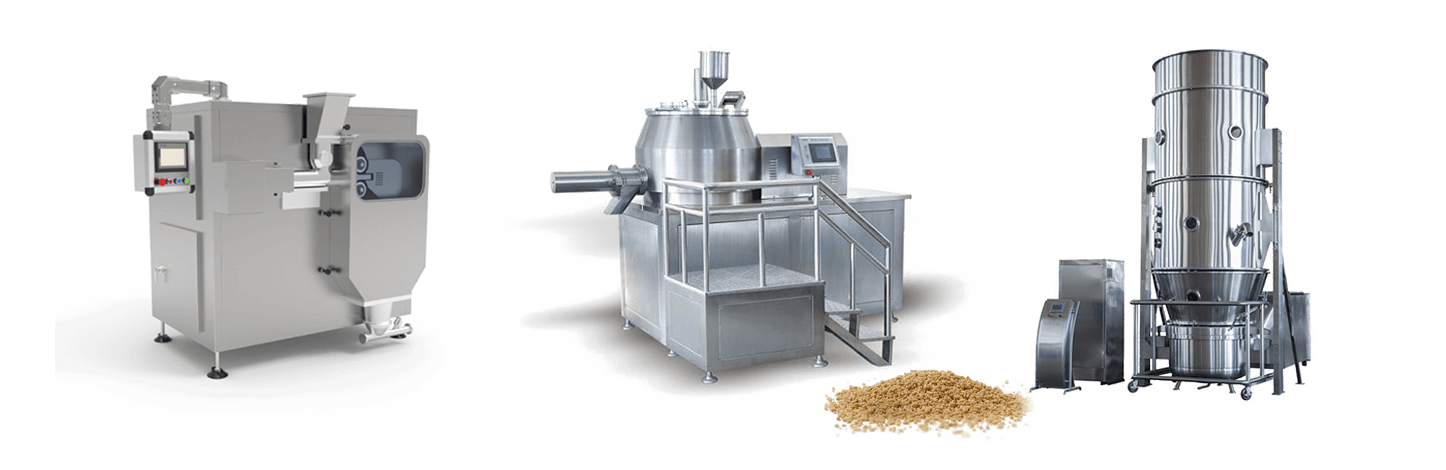

What are the advantages and disadvantages of dry granulation and wet granulation?

Dry granulation allows powder to be directly turned into granules without the addition of any binders or additives, making it easier to control the production process and material composition. However, it is generally more limited in terms of the types of materials that can be processed. Wet granulation, on the other hand, involves the addition of a liquid binder to improve the uniformity of granules, making it suitable for a wider range of materials. The downside is that it requires more equipment and steps, and the drying process can be time-consuming.

-

Does the dry granulation machine require a binder?

No, the dry granulation machine does not require a binder. It works by directly compressing the powder into granules without the need for additional binders or additives.

-

How long does one batch of wet granulation typically take?

One batch of wet granulation typically takes 10-15 minutes.

-

Can the particle size in a dry granulation machine be adjusted by changing the screen?

Yes, different mesh screens can be used for granulation according to the customer's requirements to achieve the desired particle size.

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China

399 Dongxin Road, Ruian Economic Development Zone, Wenzhou City, Zhejiang Province, China